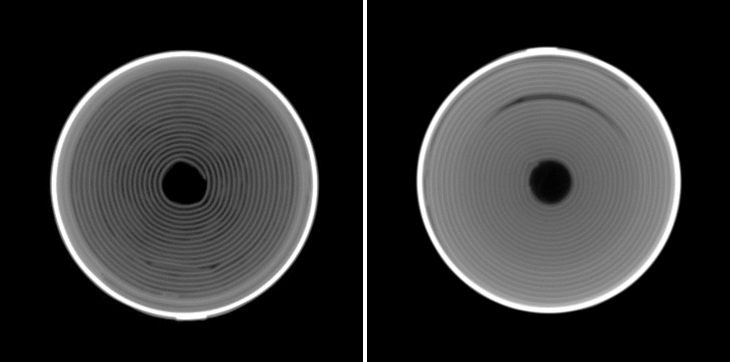

Most major Li-ion cell manufacturer inspection every single cell as part of automated quality control by automated X-ray inspection systems.

Battery of General electronics

For Electronics, Home appliances, Digital Cameras, Etc.

SEC Co., Ltd / SEC Europe Head Offcie / Automated X-ray Inspection / Nanotech Digital GmbH / Analysis report

» Analysis systems : by SEC Co.,Ltd

» Inspection method: 2D and 3D

» Model type: Stand-alone, Semi auto

» Model name: SF160FCT

There are two basic types of battery failures.

First, There are connected with a design flaw related to the electrode, separator, electrolyte or processes.

The more deeply failures are random events that do not point to a design flaw. It may be a stress like charging at sub-freezing temperature, vibration, or a fluke incident.

A mild short circuit causes high self-discharge.

So, heat build up damage the insulation layer in a cell and cause an electrical short.

The temperature can reach over 500 Celsius, at which point the cell catches fire or it explodes.

Incorrect uses of all batteries are excessive vibration, elevated heat and charging Li-ion below freezing.

If recharged, the cells might become unstable, causing excessive heat or showing other anomalies.

Most major Li-ion cell manufacturer inspection every single cell as part of automated quality control by automated X-ray inspection systems.

Automated X-ray system examines defects such as bent metal or mild short.