Camera module of Automotive and Samrtphone

For Automotive, ADAS, Smartphone, Camera application

SEC Co., Ltd / SEC Europe Head Offcie / Automated X-ray Inspection/Nanotech Digital GmbH / Analysis report

» Analysis systems : by SEC Co.,Ltd

» Inspection method: 2D

» Model type: Full-Auto

» Model name: X-eye 6100

Also, we use a smartphone camera to remember the moment of our lives.

We need to minimize the movement of the smartphone to take a picture of the moment.

But cameras have also evolved in recent years.

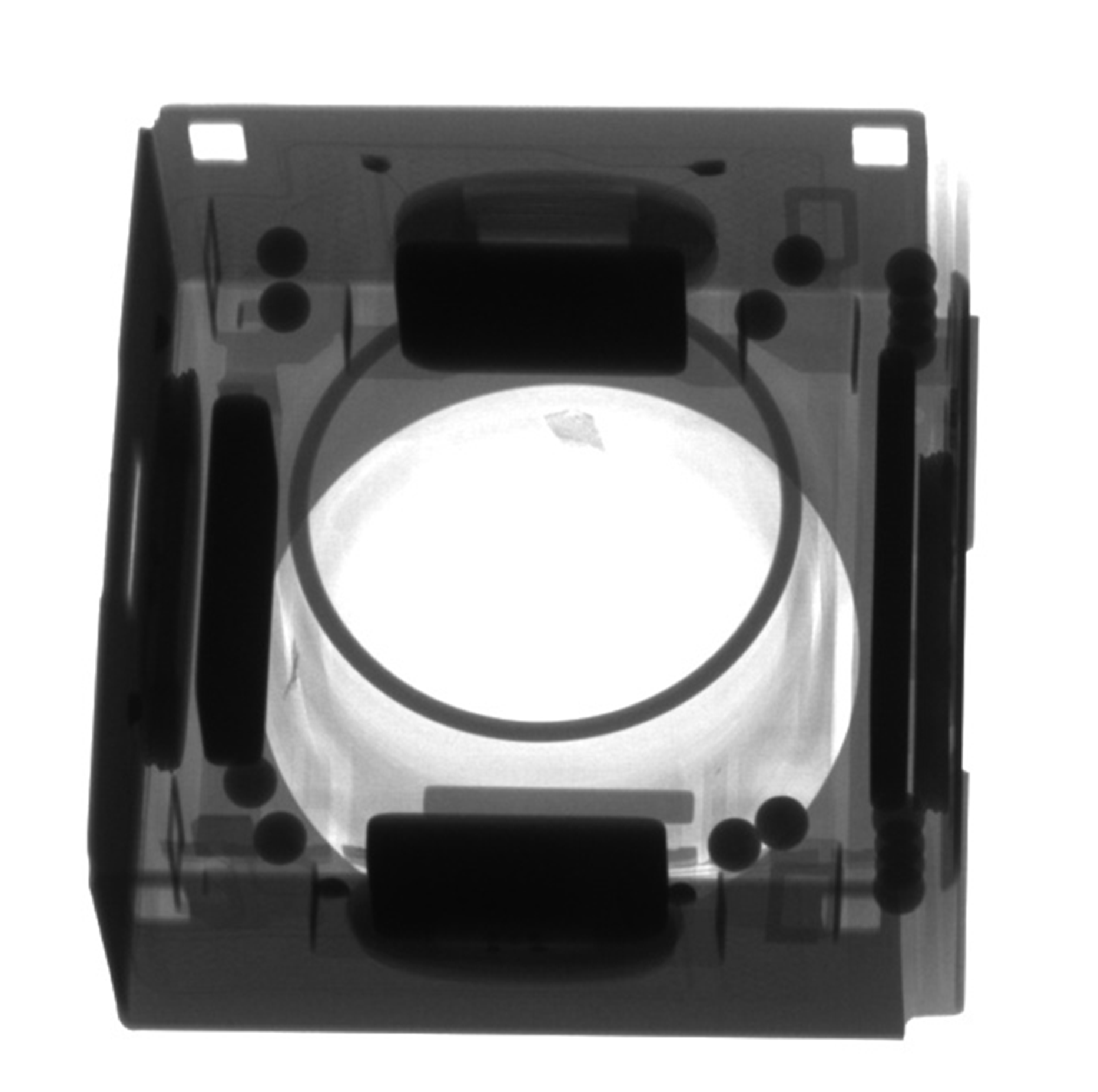

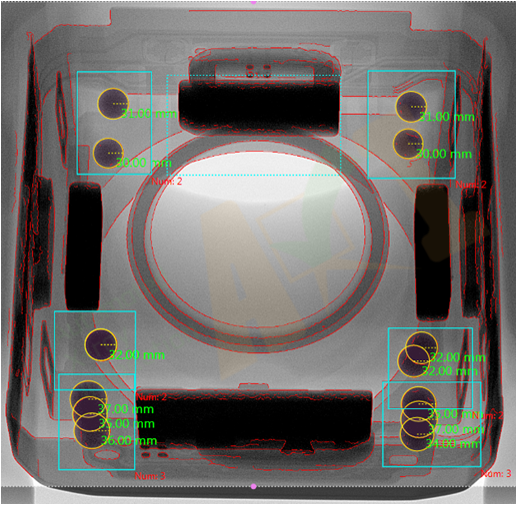

X-ray image of Rear camera module

This function is called “OIS” and helps your smartphone take pictures normally in situations where it is shaking.

A small ball bearing inside the camera lens helps the camera lens to be in its normal position from shaking.

Small ball bearings should be assembled to protect them and lenses when in the correct position. It is impossible to check visually after assembling, so customer can check it through X-ray inspection.

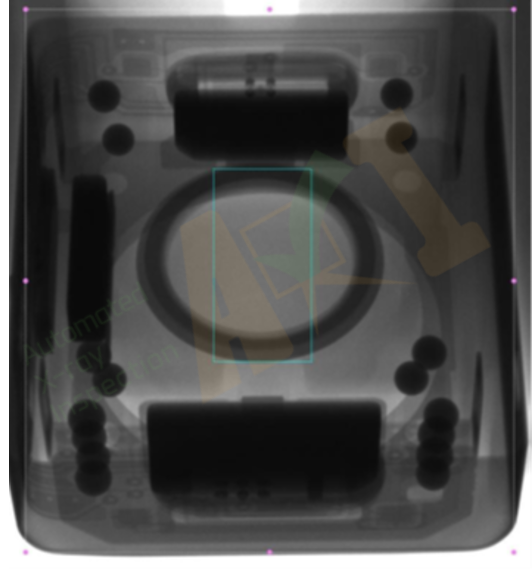

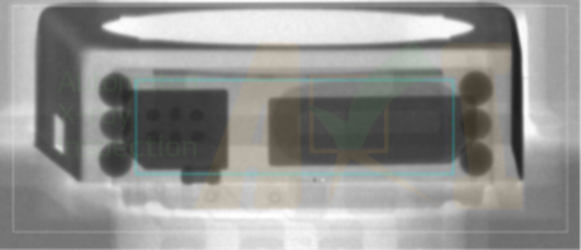

Rear camera moudule inspection image

X-ray offers a variety of support for camera module inspections and allows customer to perform inspections of the insertion order, size, position, particles, etc. of the ball.

As a solution, we generally adopt a method of inspecting by applying a slope of at least 10 degrees as shown in the right side image.

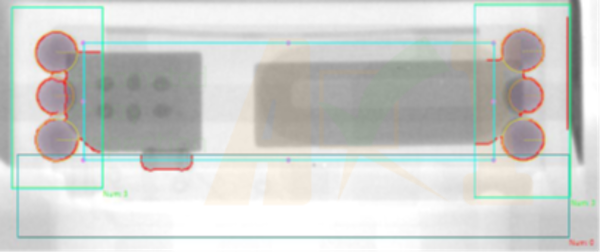

Rear camera module X-ray inspection result

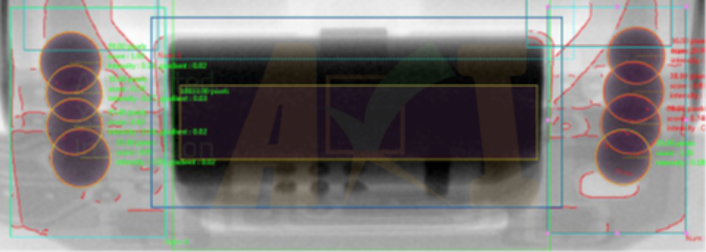

In the case of the front camera module, the product has less balls and limited inspection area compared to the rear camera module.

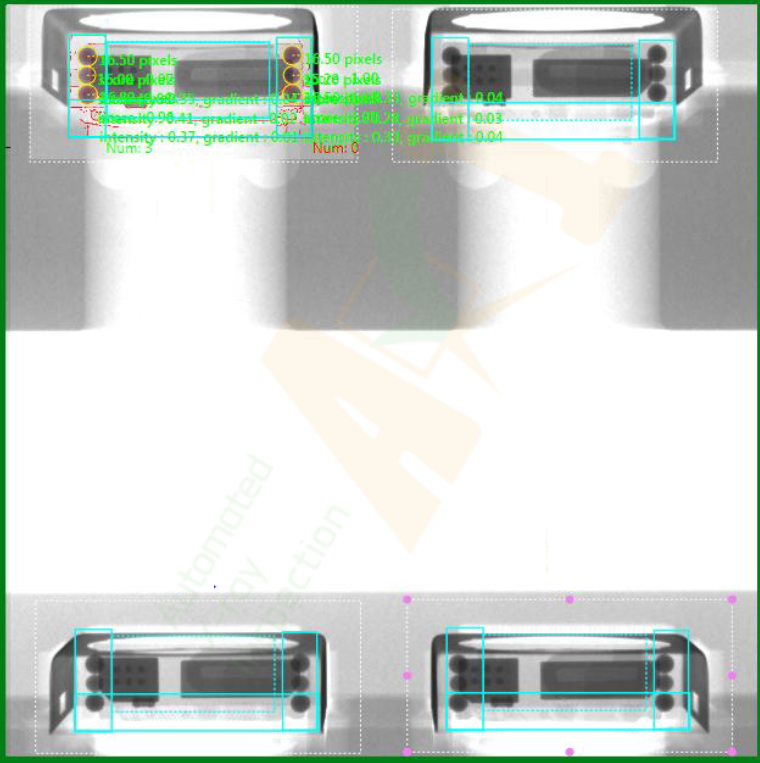

Front camera module inspection image

CONTACT

Therefore, 4 products can be inspected in 1FOV as shown in the left inspection image.