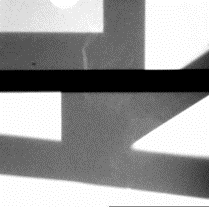

Cracks degrade the surface quality of the die and consequently the surface of the casting.

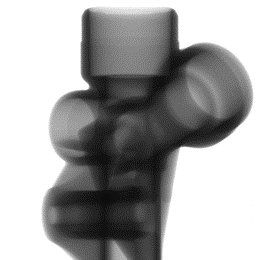

Die-casting ( Aluminum valve )

For Automotive, Industrial equipment

SEC Co., Ltd / SEC Europe Head Offcie / Automated X-ray Inspection /Nanotech Digital GmbH / Analysis report

» Analysis systems : by SEC Co.,Ltd

» Inspection method : 3D

» Model type: Stand-alone

» Model name: X-eye 7000BS

Cracks degrade the surface quality of the die and consequently the surface of the casting.

In the die casting production process, the mold is repeatedly heated, and microcracks are generated due to the molding surface and internal deformation.

In addition, the die-casting industry is operating types of equipment using ASTM standards.

This inspection equipment seires can accurately determine the location of cracks through 3D images.

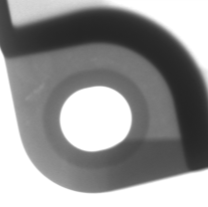

These reference radiographs illustrate the categories and severity levels of discontinuities that may occur in aluminumalloy and magnesium-alloy die castings.

X-ray systems of SEC Co.,Ltd can inspect various defects such as void, crack, fragmentation and etc…