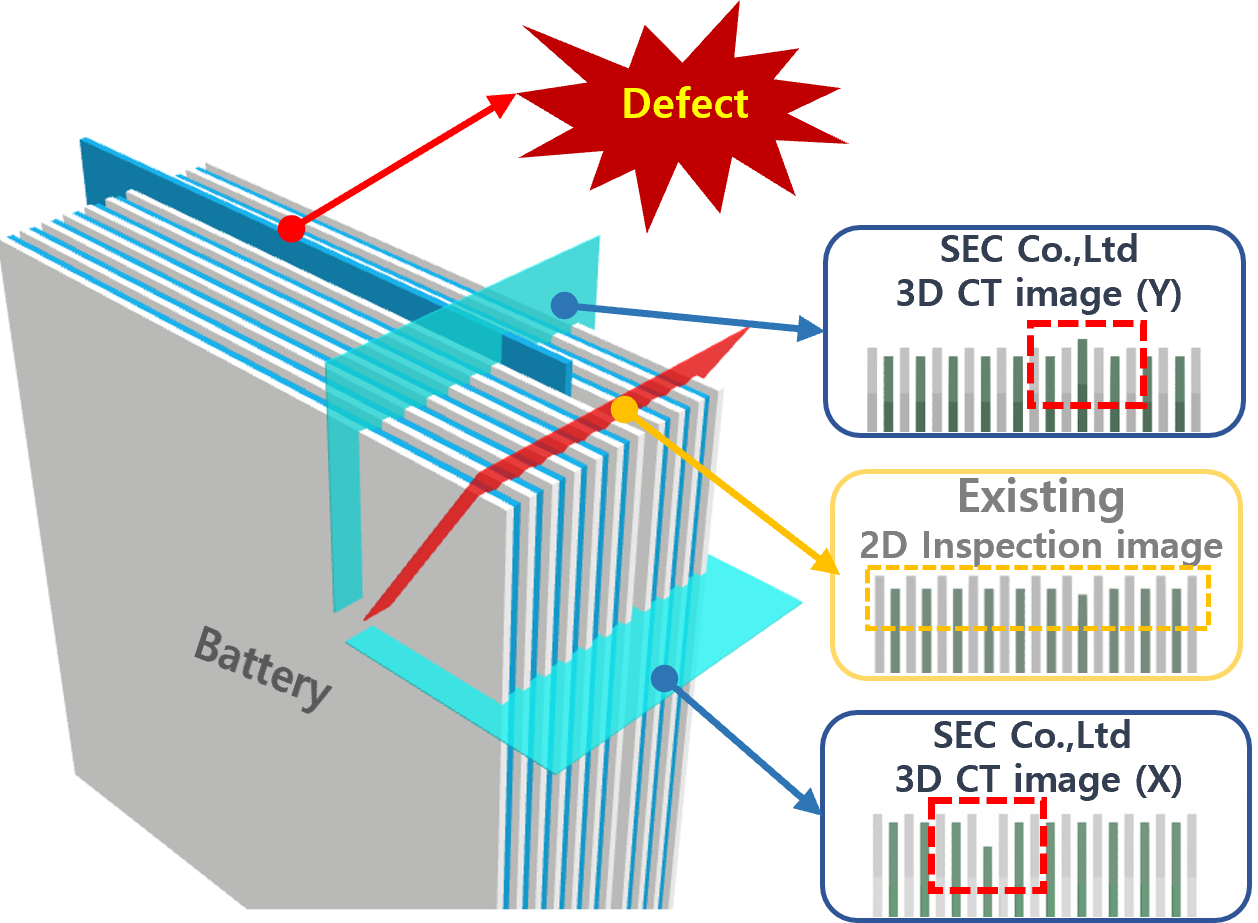

Anode/Cathode alignment and electrode gap inspection in the assemble process.

EV Battery X-ray Inspection

For Automotive, Battery, Smartphone, application

SEC Co., Ltd / SEC Europe Head Offcie / Automated X-ray Inspection/Nanotech Digital GmbH / Analysis report

» Analysis systems : by SEC Co.,Ltd

» Inspection method: 3D

» Model type: AXI

» Model name: EVB-CT

New cells are being developed for the electric vehicle and energy storage systems.

Prismatic and pouch cell are leading the new cells battery market.

But, many manufacturers have problems new cell types with high storage systems.

Most major battery manufacturer inspection every single cell as part of automated quality control by automated X-ray inspection systems.

Automated X-ray system examines defects such as bent metal or mild short.

The X-ray inspection should be conducted for the following reasons.

Battery types

If shorted, an unprotected Li-ion cell will vent with flame. Cells can also be damaged by stress related to heat, shock, vibration and incorrect charging or loading.

Lithium-based cells can build up an internal pressure under certain conditions, and a bloated pouch cell is proof of this.

Battery inspection method

In addition, it is possible to prevent electric vehicle fires and accidents through potential defect inspection through battery Anode/Cathode alignment and electrode gap inspection in the assemble process.

2D image of EV-Battery

(Current inspection method)

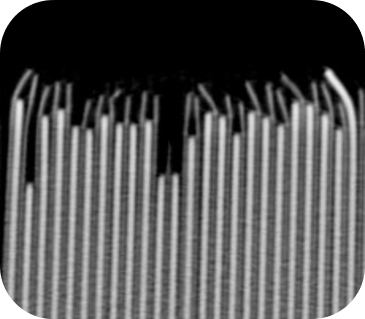

3D image of EV-Battery(SEC Co.,Ltd)

In the case of an existing X-ray inspection, the difference in the gap between anode and cathode may not be known.

SEC’s X-rays enable 3D inspection to find previously Unable inspection gaps.