core inspection technology of design / mass production to maintain quality up to EOL( End of life )

High quality 3D automated X-ray inspection system(X-eye 6300NTI)

For Automotive, ADAS, Smartphone, Camera application, PCB, General electronic board

SEC Co., Ltd / SEC Europe Head Offcie / Automated X-ray Inspection/Nanotech Digital GmbH / Analysis report

![[Nanotech Digital GmbH]Automated x-ray inspection, AXI,X-eye 6300](http://automatedxray.com/wp-content/uploads/2021/07/Nanotech-Digital-GmbHAutomated-x-ray-inspection-AXIX-eye-6300.png)

» Analysis systems : by SEC Co.,Ltd

» Inspection method: 3D

» Model type: Full-Auto

» Model name: X-eye 6300NTI

» Tact time: 1sec ~ per 1 FOV (Field of view)

![[Nanotech Digital GmbH]Automated x-ray inspection, AXI, inspection image](http://automatedxray.com/wp-content/uploads/2021/07/Nanotech-Digital-GmbHAutomated-x-ray-inspection-AXI-inspection-image-1.png)

X-eye 6300 model is a full-auto inspection system that can minimize human errors.

And core inspection technology of design / mass production to maintain quality up to EOL( End of life )

X-eye 6300 is best 3D CT AXI solution for its high image quality and inspection

reliability. This system and hybrid tube are developed, manufactured by its own

SEC technology.

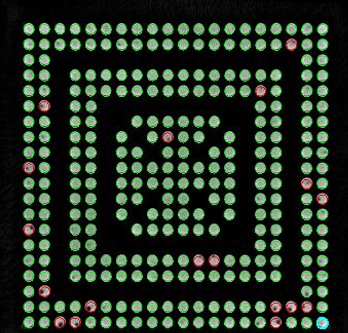

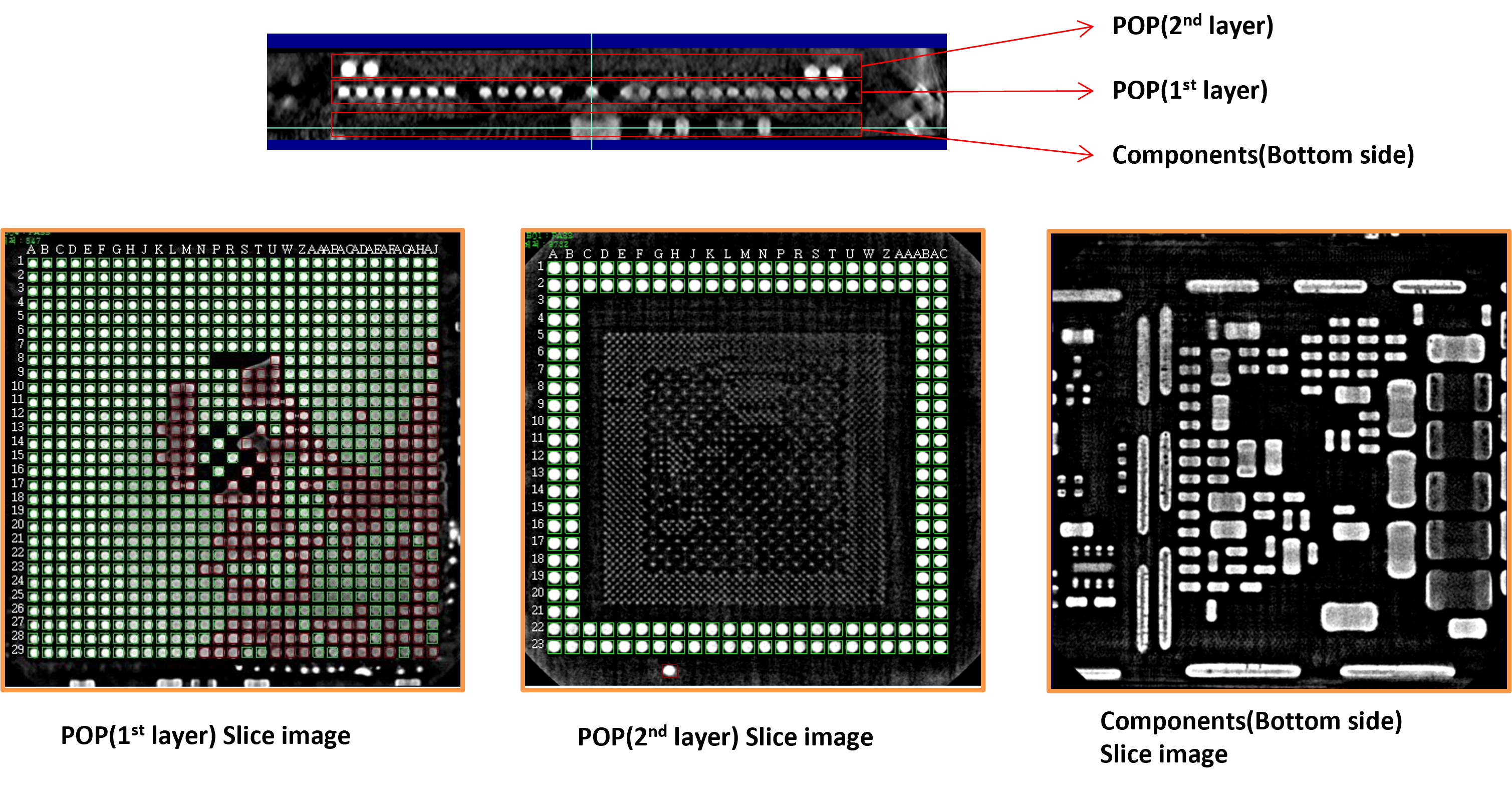

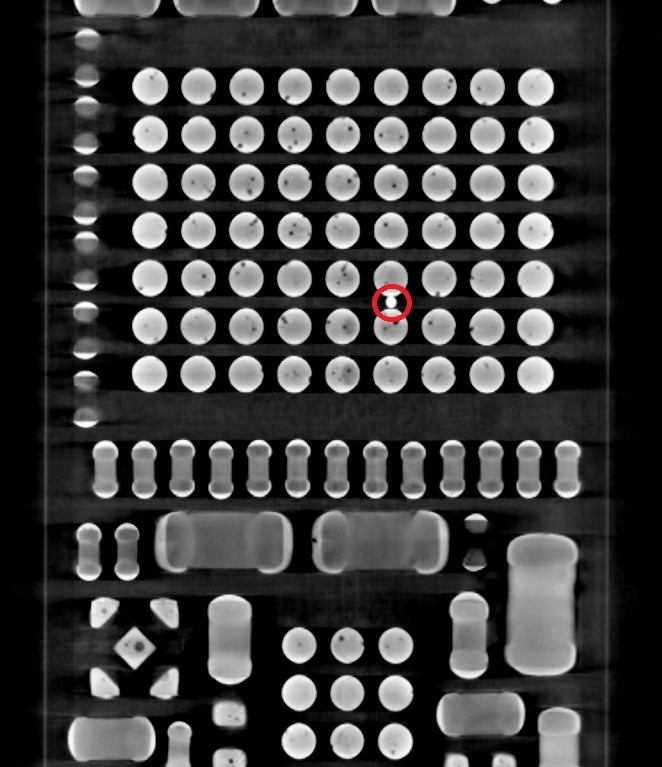

Autoamted X-ray inspection result of 3D fast scan by X-eye 6300

Judge the void defect in case that void volume measurement of the total volume measurement is not qaulified the standard void measurement

- Measure the variation of the ball size of each layer size

- Judge the HIP defect, with graph variation

- Judge the Short defect, in case that there is an object in more than two inspection areas

- According to standard volume or diameter, judge the small and big defect

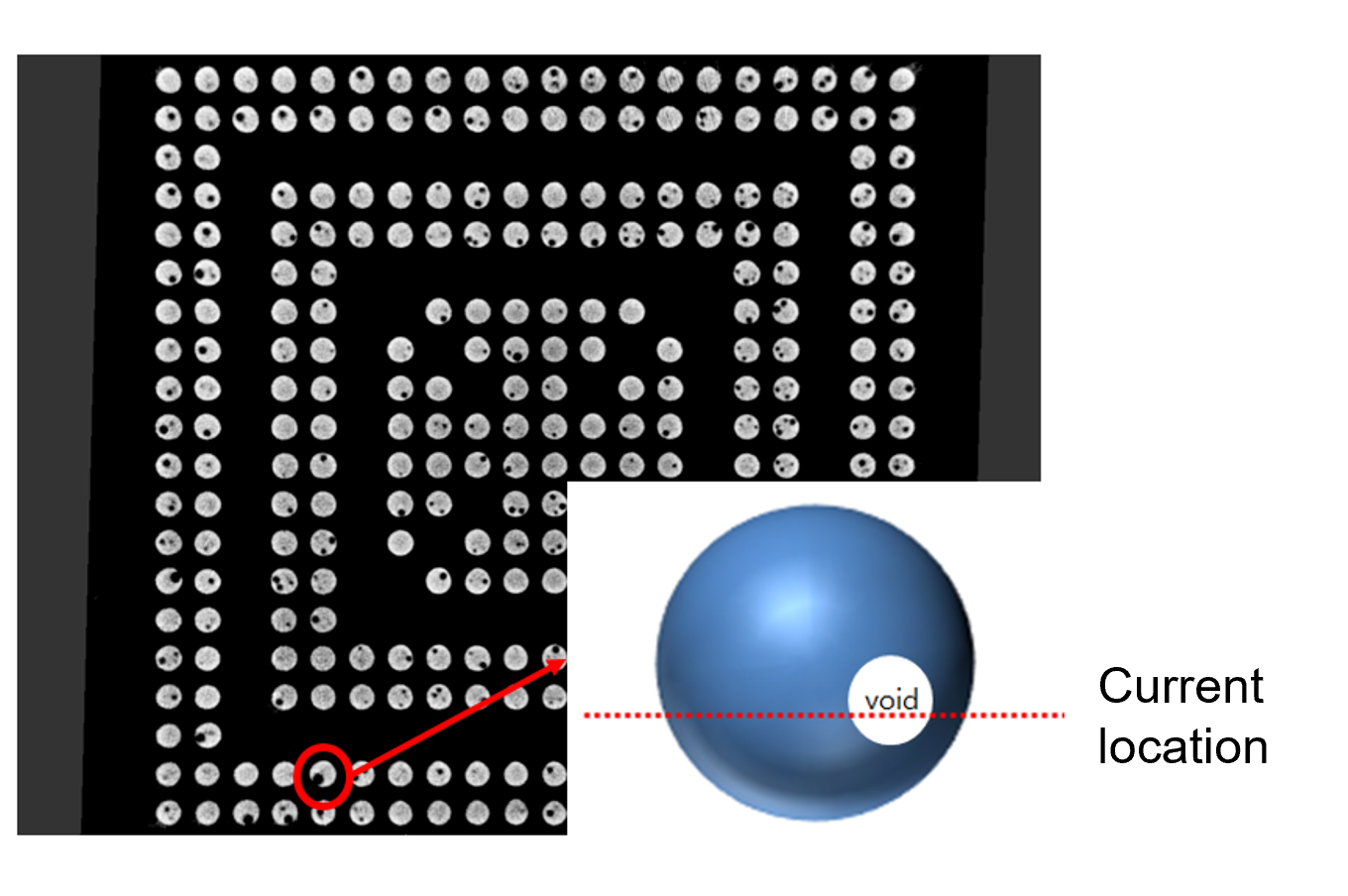

Slice inspection image with automated x-ray system

Voids’ location, size, and depth of the void can be known through the sliced X-ray image with 3D automated X-ray inspection system.

- AOI : Impossible to inspect ineternal images

- 2D X-ray : Not easy to inspect the images due to overlap images

- 3D X-ray : Available to inspect with slice images

Automated X-ray Inspection results

HIP

Particle in BGA