Voids have factors that reduce reliability,and managing this is one of the factors that increase reliability

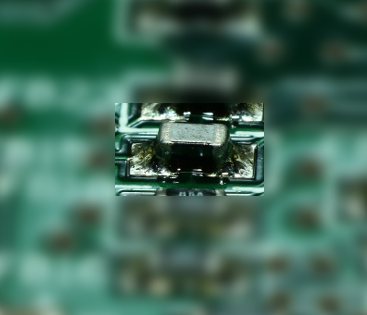

SMD resistor of PCB

For Electronics, PCB borad, Computer, ETC.

SEC Co., Ltd / SEC Europe Head Offcie / Automated X-ray Inspection / Nanotech Digital GmbH / Analysis report

» Analysis systems : by SEC Co.,Ltd

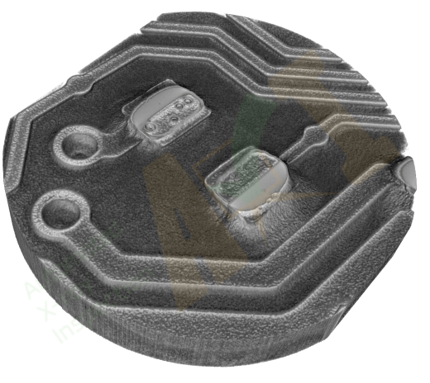

» Inspection method: 3D

» Model type: Stand-alone, Semi auto

» Model name: SF160FCT

Voids in solder gaps are one of the main problems especially for electronics board and PCB industry.

Voids can be found in BGA solder balls, or between solder joints and BGAs, or between solder joints and PCB.

This can be caused by voids in the original solder ball, or during the reflow process.

Voids could be a cause for tilting of chip components and making cracks between chip components and solder.

Also, This is tightening the problem of not evenly distributed current or part heat and is causing stress and cracks.

Also, This is tightening the problem of not evenly distributed current or part heat and is causing stress and cracks.

Voids have factors that reduce reliability,

and managing this is one of the factors that increase reliability.

Most major EMS Companies or automotive manufacturers inspection Voids and crack as part of quality control by SEC Co., Ltd X-ray inspection systems.